The manufacturing of perforated strips is far from a sterile operation in which robotic arms move silently around and every once in a while, someone with a tablet comes in to check on them. It has much more in common with traditional mechanical engineering with a hint of tailoring. The strip, made from deep-drawing, ferritic low-carbon steel, must be perforated to enable the exchange of a certain amount of electrons between the positive and negative electrode that generates current. The strips are perforated by a set of thin needles that must be inserted into the special die by hand.

But the whole process starts by placing a coil of the non-perforated strip on a stand that is often nicknamed a film projector” because it largely follows the same basic principle. The strip goes through the machine to be wound on another coil; inside the machine, however, it is perforated by hundreds of thin needles set in a die about the size of a thimble. These needles are placed in the die with maximum precision, fixed, covered in special glue, and hardened in a kiln.

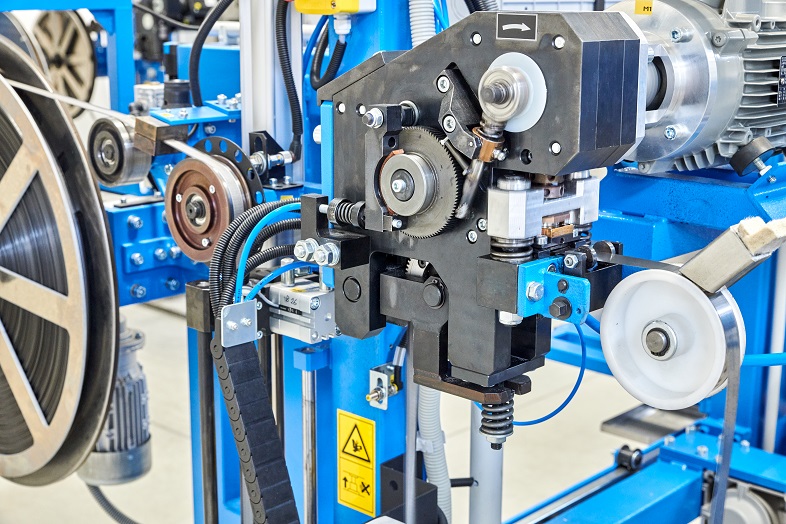

The resulting perforation tool then oscillates within the stand to create open surfaces on the strip. The perforation is immediately checked using light; while still inside the machine, the strip is illuminated so the operator can fine-tune the machine to ensure that the open area of the strip is within the required parameters. The mechanical movement of the strip under the perforation tool is provided by stepper motors; the winding is optimized so there is no need to tighten the finished coil.