Powering the Workers' Paradise. History of GAZ part III

History

July 11. 2024

2 min.

In the aftermath of WWII, the GAZ site in Zwickau almost ceased to exist. But in the decades to follow, the company grew to become an important element of the East German economy.

A few weeks after it was severely damaged during an USAF air raid on Zwickau, the factory in Reichenbacherstraße was liberated by the US Army on April 17, 1945. Nevertheless, in compliance with the outcome of the Yalta Conference, Zwickau found itself in the Soviet occupation zone. By September that year, the company was already under Soviet military administration and ownership of the USSR. Although, as part reparations claimed by Poland, the entire factory was to be disassembled and shipped to the war-ravaged country.

At the same time, however, the Soviets required the facility to keep on producing miner's lamps and other lighting appliances as compensation for Soviet war damages. Therefore, when the Poles arrived on site in March 1946, they limited their demands to only the three production lines for lead acid batteries. This would mean the cessation of battery production in Zwickau, which was needed for Soviet vehicles and other equipment in Germany. So, the Soviet command intervened and a third of the claimed machinery was allowed to stay in Zwickau.

In August 1947, the facility was fully integrated into a Soviet company and renamed Grubenlampenwerke Staatliche A.-G. der elektrotechnischen Industrie – Kabel. At this point, the headquarters of the Friemann & Wolf, the pre-1945 corporate entity, has been moved to Duisburg in the British occupation zone. A significant exchange of goods and money between Zwickau and Duisburg was maintained at least until September 1947 but was eventually severed not least on the grounds of secrecy, as the lamps manufactured in Zwickau were used for uranium mining in the Ore Mountains along the Saxon-Bohemian border.

Property of the People

At the turn of the decade, Grubenlampenwerke was undergoing a significant restructuring while, after several years of just repairing and shrinking the facility, new construction projects were started. These included a grocery store on the premises or a kindergarten, as many workers were women due to the fact that more than a million German men have still not returned from, or died in, Soviet war captivity. Then, in April 1952, the USSR gave the factory back to the GDR while the Soviet management was bid a celebratory farewell in keeping with the motto of everlasting German-Soviet friendship.”

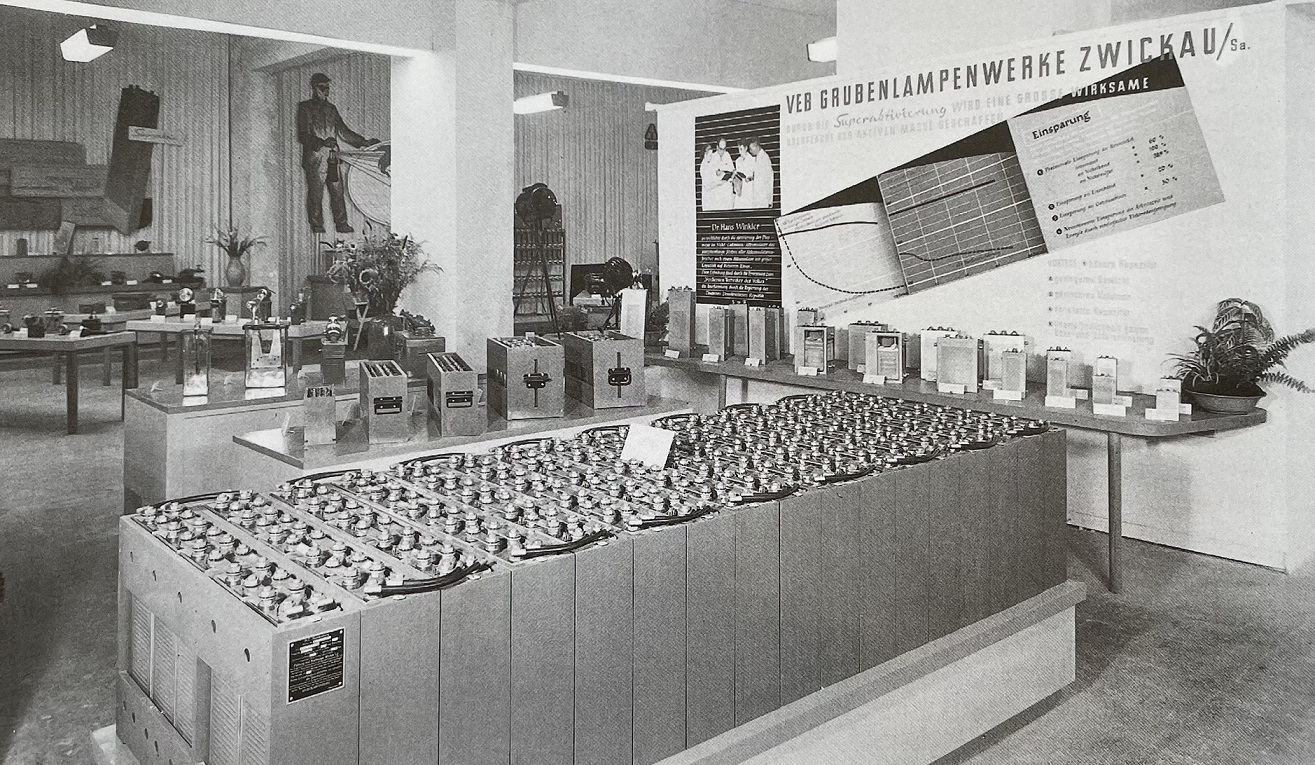

The factory was now turned into a VEB, or state-owned enterprise, and renamed Grubenlampenwerke Zwickau/Sa., or GLZ. The production of carbide lamps ceased in 1958, and that of gasoline lamps in 1960, with the company henceforth manufacturing electric miner's lamps only. Both these as well as lead-acid and nickel-cadmium batteries made by GLZ were now exported across the Eastern Bloc. In 1955, a new and more automated assembly line was opened which, together with later measures, resulted in the total production volume increasing 17-times between 1952 and 1978.

In July 1968, GLZ was, along with four other companies, incorporated into the Kombinat VEB Galvanische Elemente, or galvanic elements, which was later attached to a different kombinat specialized in automotive electronics. (Kombinats, or combines, were industrial conglomerates common in Eastern Bloc countries.) It was at this time when the Council of Ministers of East Germany, or the GDR's government, decided to increase the domestic production of vehicles including the legendary Saxon Porsche, that is the Trabant.

And GLZ was foreseen to supply all of them with batteries so that the GDR's automotive sector would not have to rely on imports in this regard. Thus, a new production hall was opened in 1978. Equipped with the latest technology, mostly imported from the West, the new production line allowed GLZ to ramp up production to 1.2 million car batteries per year. After that, some 80 percent of the company’s production portfolio were car batteries, 10 percent Ni-Cd cells and 5 percent various lighting appliances. Once the factory’s main produce, mining equipment amounted to only 5 percent.

All in all, it was in pretty good condition that GLZ entered the eighties. A major modernization and expansion were in the planning, intended to keep the company at the forefront of battery technology in the Eastern Block well into the 2000s. Or at least unless something unexpected happens, right. Stay tuned for the next installment of our series on the history of GAZ which will be published soon.

| Mentioning the Trabant: All of the 3.1 million Trabbis ever produced were manufactured in our city by VEB Sachsenring Automobilwerke Zwickau. If you come to Saxony, don’t forget to visit the August Horch Museum which covers the history of automobile construction in Zwickau from Horch and Audi to Trabant and beyond. |

Similar articles

Coming Back Stronger. The History of GAZ part IV

November 21. 2024

2 min.

ViewFrom Now on Electric. The History of GAZ part II

March 29. 2024

2 min.

ViewBringing Light into Darkness. The History of GAZ part I

January 3. 2024

2 min.

View